|

DOWNLOADS

|

COMBUSTION INTENSIFICATION TECHNOLOGY

Combustion intensification technology (CIT) allows decrease of burned fuel consumption at heat generating plants of different capacity by 1,0…3,6%, decrease electrical energy consumption for personal needs (at smoke exhausters and blow fans), concentration and gross emissions of hazardous substances to the atmosphere.

CIT can be used at functioning and newly put into operation heating units of heat-and-power engineering, utility service and agriculture, at each enterprise of any branch of industry where fuel is burnt with the help of burners.

Technical aspect

CIT was developed as a result of numerous researches and tests and in 2003 it was put into commercial operation at the objects of heat-and-power engineering and industrial enterprises of Ukraine.

The technology provides for air passing through non-uniform permanent electrical field and electrical ionization of the air before it is supplied to burning area. Oxygen that is contained in the air increases its reactivity and decreases activation energy of chemical reactions of burning. This leads to full burning of fuel and stabilization of the process of burning, decrease of chemical and mechanical underburning.

In addition to improvement of the process of burning the quantity of air supplied for burning is decreased and as a result the loss of heat is decreased as well as the gases emitted to the atmosphere, the concentration of nitric oxide NO

x

, sulfur SO

2

and gross emissions of all the hazardous substances.

As a result the fuel combustion intensification technology (CIT) allows boiler units to operate in compliance with the technological requirements, increased efficiency coefficient and decreased (close to stoichiometric ratio) excess air.

Economical aspect

Commercial operation and results of independent ecological and thermotechnical tests carried out by the specialized enterprises confirm:

• increase of efficiency "gross" of the boiler within the limit of 1…3,6 %;

• annual fuel economy within the limit of 1…3,5%;

• decrease of electrical energy consumption for personal needs 0,21% at average operational load of a power-generating unit;

• heat power plants (HPP) or heat stations (HS);

• attainment of annual economic effect 300 000…700 000 $ for boiler units of HPP;

• high payback of the technology: 1…1,5 years.

Ecological aspect. Kyoto protocol

Ecological effect of BIT utilization can be used in accordance with the terms and conditions of Kyoto protocol, ratified by Ukraine on February 4, 2004. Validation of the project is technically easily realizable. The characteristics of operation allow recording of ecological effect within 6-8 hours of the work of the boiler equipped with BIT.

Testing of boiler units equipped with BIT showed that at normal load of the boiler unit:

• emissions of carbon dioxide (ÑO2) are decreased by 7-10%;

• nitric oxide (NO x) is decreased by 20…30 %;

• sulfur oxide (SO2) by 10…40%;

• quantity of emitted combustion gas by 5…10%.

Advantages of BIT

• Burning intensification technology has no industrial analogues and competitors in "costs-result" relation. In contrast to BIT the use of other methods of intensification of burning with analogous results requires capital investments and time spending for reconstruction and modernization of the functioning power equipment, industrial testing and approbation.

• BIT units are produced by the corporation "PromEkonomService" in cooperation with some research institutes and industrial enterprises of Ukraine and Russia equipped with modern equipment that provides for high degree of industrial and technological effectiveness of their production.

• Introduction of BIT units. The general duration of works on introduction of BIT at one boiler unit comprises 2-3 months: design, production, assembling, checkout, approval of the necessary documentation by the corresponding bodies. Assembling of equipment at one boiler unit does not exceed 10 days.

• Installation, assembling checkout and startup of the BIT units can in accordance with the instruction be carried out with the help of field personnel of the client.

• The unit operates in automatic mode, its maintenance does not require special training of the field personnel and their constant presence during its operation.

• Several modifications of BIT are carried out taking into account the capacity of the fuel consumption plants.

• To operate the heating process of boiler units and to control emissions of hazardous substances to the atmosphere stationary gas-analyzers are used;

Equipment

BIT equipment is reliable, compact, meets the requirements of safe exploitation and manufactured by the corporation "PromEkonomService" on cooperation with some research institutes and industrial enterprises of Ukraine and Russia. To operate the process of burning in the boiler units and to control emissions of hazardous substances into the atmosphere stationary gas-analyzers on determination of carbonic and oxygen dioxide in the mode section are included to the set of supply.

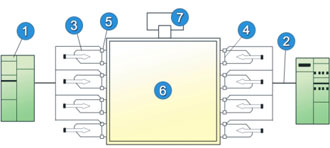

The scheme of installation of BIT unit at the standard boiler unit

1. Cabinets for installation of high-voltage equipment, that include:

• high-voltage transformer rectifier that increases feeding voltage and carries out transformation of alternating current with the frequency of 50 Hertz to direct current with peak voltage of up to 27 kWt, • block and panel for control and indication of electrical parameters and operation modes. 2. High-voltage heat-resistant cable (up to 200 °Ñ) provides for high voltage supply to ionizing grids. 3. Metal boxes for air conduits.. 4. Ionizing electrode grids supported by special ceramic bushing and base insulators that stand the temperature of up to 600 °Ñ. 5. High-voltage bushing insulators. 6. Boiler. 7. Standard gas-analyzerof Î2 and ÑÎ content in combustion gases of mode section of the boiler unit. Technical characteristics of high-voltage BIT equipment:

Licensing

Financial and legal model that the corporation follows is based on operations with the objects of intellectual (industrial) property and receiving of rewards in the form of royalty.

The size and the procedure of royalty payment are determined by the terms of the license contract.

Royalty charge and payment is carried out from the achieved economic and ecologic effect of the use of RAU.

In connection with theintellectual property right BIT is protected by the Certificate ¹7194 of 27.02.2003 for scientific development "Burning intensification technology BIT" as well as the Certificate ¹10299 of 18.06.2004 for scientific work "Authorial operating system "SOM issued by the State Department of Intellectual Property of Ukraine.

In connection with the industrial property BIT is protected by the Patent of Ukraine ¹ 52845 of 15.01.2003 for invention of the device of oxidant preparation for fuel burning, by international European, Eurasian patents in accordance with the procedure of ÐÑÒ (international edition of WIPO ¹ WO 03/102469 À1 of 11.12.2003). Loading

|

|

||||||||||||||||||||||||||