|

DOWNLOADS

|

REAGENTLESS ANTI-SCALE UNIT

Reagentless anti-scale unit for water treatment (RAU) is designed for prevention of scaling on heat-exchanging heating surfaces. RAU can be used for water treatment before its supply to hot-water boilers, heat-exchanging apparatuses for heating of water for different purposes, cooling air jackets of technological equipment.

RAU can also be used foe treatment of water for the heating system and hot-water supply system as well as for the systems of air coolers, oil coolers of compressor stations and cooling elements of equipment of steel plants and by-product coke plants.

Technical aspect

Oxidation-reduction electrochemical reactions that proceed in reactors of RAU when the electric current runs through the treated water provides for stable suspension that does not deposit on heat-exchange surfaces due to low dispersibility of generated particles.

A great number of centers of crystallization generated in reactors results in salt precipitation in the volume of liquid and not on the heat-exchanging surfaces. Potentially hazardous superfine particles of calcium carbonate, magnesium and ferric compounds are deposited on cathode surfaces and atomic oxygen dissolved in water interreacts with graphite anodes of the anti-scale unit.

The use of RAU provides for protection of heat-exchanging unit from scale and corrosion that allows it to work with high efficiency coefficient for a long period of time. The work of RAU is more effective at hot-water supply heaters where there is no alternative to the present method of stabilization of water treatment.

Economic effect of RAU utilization:

• fuel economy up to 10%;

• electric power economy up to of 8-10 % (for compressor stations);

• decrease of expenses for cleaning and repair of equipment;

• refusal of expensive chemical reagents;

• high payback of the technology within approximately 1,5 - 2 years depending on heat productivity of the boiler-room and water consumption for hot-water supply.

Ecological aspect. Kyoto protocol

Due to the refusal to use chemicals necessary for water preparation and acids use at the cleaning of thermotechnical equipment toxic flowings are decreased. Increased efficiency of thermotechnical equipment results in fuel economy and decrease of ÑO2 and other hazardous substances emissions to the atmosphere and this meets the requirements of Kyoto protocol.

Advantages of RAU

• Reagentless anti-scale unit assembling of which is carried out within 3-4 hours is reliable and efficient in operation.

• Parameters of the control system are set by the microprocessor system on the basis of consumption, state of reactor, temperature of the treated water, etc. All the parameters are shown at the display of the control system of RAU and are filed in the archive of the microprocessor for the following reading and analysis of the work.

• Additional personnel for its maintenance are not necessary.

• RAU allows saving fuel and energy by means of scale prevention in heat exchangers as well as fuel economy at water heating.

• The use of RAU allows elimination of fouling in the water supply system.

• Typical range of reactors has the capacity of 50, 100 and 200 m³/h, modular construction allows to increase the productivity of the system up to 1000 m³/h and more.

• Maintenance of devices lies in periodic control of electric parameters. Electrode cleaning is carried out by mechanic method as well as by change of direction of electrolysis with the set temporary parameters.

• Consumption of electric power for preparation of water is equal to approximately 1 Wt/m³.

Equipment

Equipment

RAU equipment is reliable, compact and meets the requirements of safe exploitation.

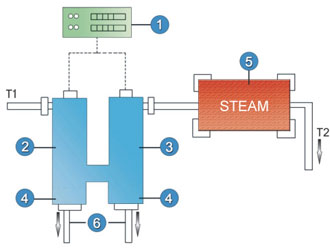

Scheme of Installation of RAU

1. Power and automatic control unit.

2. First reactor. 3. Second reactor. 4. Sedimentation tanks. 5. Water-steam heat exchanger. 6. Sediment discharge. T1. Conditioned water. T2. Heated water. General technical characteristics:

Licensing

Financial and legal model that the corporation follows is based on operations with the objects of intellectual (industrial) property and receiving of rewards in the form of royalty.

The size and the procedure of royalty payment are determined by the terms of the license contract.

Royalty charge and payment is carried out from the achieved economic and ecologic effect of the use of RAU.

Method and concrete technical solutions of the system are protected by the protective documents and constitute intellectual property of the Corporation "PromEkonomServicee":

• Copyright certificate ¹ 15418 "Scientific work "Technology and authorial operating system of electrical and stabilization preparation of water "S.E.P." in heat generating units";

• Copyright certificate ¹ 16487 "Scientific research "The electrolysis plant of anti-scale preparation of water for thermal networks";

• Patent of Ukraine ¹ 77143 ""Method of electrical and stabilization anti-scale preparation of water, the system and the plant which realizes it".

Loading

|

|